£

£

- Description

- Attributes

- Documents

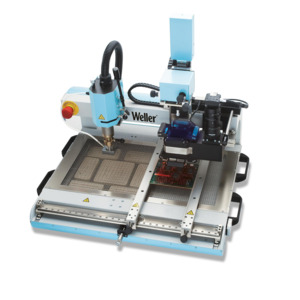

- For rework and repair of defective BGA components

- The temperature is monitored by digital control electronics

- Monitoring software determines temperature profiles and controls process

- A two-zone infrared bottom heater precisely controls pre heat

- High resolution 2 Mpix CMOS USB camera enables accurate positioning

- Interfaces with a standard PC via a USB 2.0 port

- Patented nozzles provides a finely metered heat supply to the components

- A temperature sensor prevents thermal overload of the component

As on-board components become increasingly complex, Weller® continues to lead the field with innovative, user-friendly repair and assembly tools that enable users to successfully take on increasingly demanding rework challenges.

The WQB4000SOPS (Split Optic Positioning System) is the third generation of the Weller BGA/SMT repair system. It is engineered to meet the exceptional demands placed on modern rework tools and is designed to deliver real value for your investment.

It is a comprehensive, user-friendly system for the removal and soldering of BGA components, without the risk of thermal damage to the component or circuit board.

Brand: Weller

ESD Safe: Yes

Height: 680 mm

Length: 692 mm

Temperature Range: 50 - 400°C

Type: Rework Station

Voltage: 230 V

Wattage: 2300 W

Width: 580 mm

£

£