- Description

- Attributes

- Documents

Keithley 2200-30-5 Single-Output Programmable DC Power Supply with USB And GPIB Interfaces, 30V/5A

Number of Outputs: 1

Maximum Voltage: 30V

Maximum Current: 5A

Power: 150 W

Connectivity: USB, GPIB

Features:

0.03% basic voltage output accuracy and 0.05% basic current accuracy provide quality test data

High output and measurement resolution, 1mV and 0.1mA, for testing low power circuits and devices

Remote sensing to ensure the programmed voltage is applied to the load

Dual-line display shows both the programmed values and actual outputs for a continuous indication of the status of the power delivered to the load

Repeatable test sequences of up to 80 output steps are easy to create with the built-in List mode

GPIB and USB interfaces are standard for convenient automated control

The Keithley 2200-30-5 Single-Channel Programmable DC Power Supplies provide a wide range of voltage outputs to address the testing and characterization of components, circuits, modules, and complete devices, whether you are in a research laboratory, in design and development, or in production test. The Keithley 2200-30-5 consists of five models with output voltages from 20V to 72V that can deliver 86W, 96W, 100W, and 150W of power. In addition, these power supplies can act as constant current sources as well as constant voltage sources. The Keithley 2200-30-5 power supplies offer an excellent combination of performance, versatility, and ease of use that allow you to obtain quality test data as quickly as possible. They perform as effectively in automated test systems as they do in manual instrument configurations.

Outstanding Accuracy Delivered to the Load

With basic voltage setting accuracy of 0.03% and basic voltage readback accuracy of 0.02%, you can be sure that the voltage you program for the load is applied at the output terminals. What’s more, the rear panel connections include remote sense terminals that compensate for voltage drops in the power supply leads. This helps to ensure that the correct voltage is delivered to the load terminals of the device-under-test (DUT). Great accuracy is not limited to voltage—the basic current setting and readback accuracy is 0.05%, providing you with high quality load current measurements. Also, with less than 5mVp-p noise, you can be confident that the power applied to the DUT’s load terminals is both accurate and of high quality.

Superior resolution is also provided by Keithley’s Keithley 2200-30-5 single-channel power supplies. With 1mV and 0.1mA resolution, the effects of very small changes in voltage and current can be detected and studied. For portable devices in which minimum power consumption is critical, the 0.1mA current resolution allows you to measure the idle and sleep mode currents so you can verify that your products meet aggressive low power consumption goals.

Get Test Results Quickly

Keithley’s Keithley 2200-30-5 single-channel power supplies have a number of features that enable you to obtain the results you need quickly and easily, including tools to help you create sophisticated tests for a wide range of requirements.

The dual-line display shows both the programmed settings and the actual voltage and current outputs, allowing you to immediately see, understand, and address any differences between the expected and actual output values. Multiple methods can be used to adjust the voltage and current settings. You can use the direct-entry numeric keypad to set precise voltage and current values. There is also a rotary knob with adjustable step size that lets you easily study the response of your DUT to small or large changes in voltage or current.

Need to repeat a set of tests often? Instead of programming a number of parameters for each test every time you run the test, just use a few keystrokes to save a test setup once and then recall it whenever you need it. Take advantage of 40 memory locations to save up to 40 set ups or use the Keithley 2200-30-5 List mode to define custom test sequences of up to 80 steps. This makes it easy to perform tests such as analyzing how your circuit- or device-under-test performs at each voltage level within a range of voltages. A saved test can be run manually using front panel key strokes, automatically using external trigger signals, or remotely using programmable interface commands. Up to seven 80-step lists can be stored in a Keithley 2200-30-5 single-channel power supply. Each step can have a programmable duration.

Protects Your DUT at All Times

A number of features are built into the Keithley 2200-30-5 power supplies to ensure that your DUT is protected from damage. A maximum voltage can be set so that regardless of the voltage value requested, the output will not exceed the programmed limit value. For further voltage magnitude protection, an Over Voltage protection level can be programmed that will cause the output to drop below 1V if the Over Voltage limit is reached. These protections are in addition to the Current Limit setting, which restricts the amount of current that can flow into the DUT. If the Current Limit is reached, the Keithley 2200-30-5 power supplies convert from constant voltage to constant current operation in which the current is controlled at the Current Limit setting and the voltage varies based on the load resistance.

In addition to the limit settings, you can set a timer to turn off the output after a specified time interval, allowing you to setup a test on your bench and let it to run unattended knowing that power will automatically be removed from the DUT after the programmed time has elapsed.

Ensures that Test Parameters are Not Accidentally Changed

Prevent accidental changes to settings to avoid collecting incorrect test data and wasting time repeating tests by taking advantage of the Keithley 2200-30-5’s front panel lock-out functions. You can disable the front panel knob or disable all the front panel data entry controls. When all the front panel data entry keys are disabled, the Keithley 2200-30-5 prompts for a password to re-activate the keys.

Select a Convenient Interface

The Keithley 2200-30-5 DC power supplies can be an integral part of your automated test system. You have the option to control each power supply over a GPIB interface or a USB interface. The USB interface is test and measurement class (TMC) compliant so you can use the standard SCPI command syntax. Standard drivers are included with the Keithley 2200-30-5 to simplify interfacing them into an automated test environment.

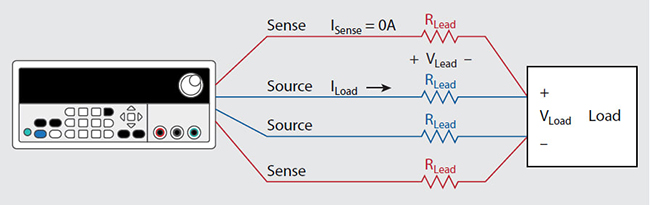

No matter how accurate your power supply output is, you cannot guarantee that the programmed output voltage is the same as the voltage at the DUT’s load. This is because a power supply with two source output terminals regulates its output only at its output terminals. However, the voltage you want to be regulated is at the DUT’s load, not at the power supply’s output terminals. The power supply and the load are separated by lead wires that have a resistance, RLead, determined by the length of the lead, the conductivity of the conductor material, and the geometry of the conductor. The voltage at the load is: VLoad = VProgrammed – 2*VLead = VProgrammed – 2*ILoad*RLead. If the load requires a high current, then ILoad is high and VLead can easily be a few tenths of a volt, especially if the power supply leads are long, as can be the case in an automated test rack. A voltage at the load could be 80mV to 160mV lower than the desired voltage (with 2A to 4A flowing through a 16-gauge wire).

The remote sensing technique solves the problem of voltage drop in the leads by extending the power supply feedback loop to the input of the load. Two sense lines from the power supply are connected to the power inputs. These sense leads are voltage measuring lines that connect to a high impedance voltage measuring circuit in the power supply. Since the voltage measuring circuit is a high input impedance circuit, the voltage drop in the sense leads is negligible. The sense lead voltage measurement circuit becomes the feedback control loop for the power supply. The voltage at the load is fed back to the power supply by the sense leads. The power supply raises its output to overcome the voltage drop in the source leads and VLoad = VProgrammed.

Thus, only with remote sensing can the accuracy of the power supply be applied to the load.

In The Box

213-CON - Rear Panel Mating Connector with Handle

CS-1638-12 - Rear Panel Mating Connector

Documentation and Driver CD

Three-year warranty